Tesla’s CEO then fesses up to his company’s build-related mistakes and dives into why they’ve been happening. When asked about panel gaps, Musk says: “It took [Tesla] a while to…iron out the production process,” going on to discuss how the company struggled to get details right while production was in “vertical climb mode.” Really early production cars, and the cars that come out after production has leveled off, Musk says, are the ones likely to have the best fit and finish.

Munro, having met with a number of Tesla owners during a recent road trip, noticed variations between two vehicles built in the same short time-span. Confused as to how this could happen, he asked Musk. “We actually did improve gap and paint quality quite a bit towards the end of last year,” the California-based engineer-CEO told the Michigan-based engineer-CEO, “Even in the course of December.”

Musk also mentions that while ramping up production, his team rushed cars in a way that didn’t adequately allow paint to dry, causing issues with quality. “Production is hell,” Musk puts it frankly.

Advertisement

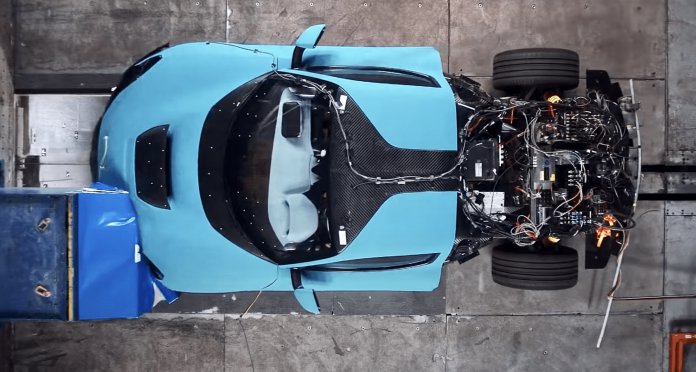

What about the rear part of the Model 3’s body, which Munro criticized for consisting of far too many pieces with far too many different fastening methods? (shown below):

Advertisement

The image above shows this problem on an early Model 3 build, though Munro’s 2021 model does show some improvement. For example, there are now 17 spot welds on one particular plate instead of 26 on the old car, and there’s one fewer bolt. Oddly, though, even newer Model 3s don’t share the Model Y’s more intuitive “mega-casting” rear wheelhouse — i.e. a single piece instead of various panels fastened together.

Advertisement

Musk discusses this Model 3 design weakness.

“The organizational structure errors, they manifest themselves in the product,” he begins. “We’ve got probably the best material science team in the world at Tesla. Engineers would ask what’s the best material for this purpose…and they got like 50 different answers. And they’re all true individually, but they were not true collectively,” he admits.

Advertisement

“When you try to join all these dissimilar alloys…you’ve got gaps that you’ve got to seal, and you’ve got to join these things, and some of them need to be joined with rivets, some of them need to be joined with spot welds, some of them need to be joined with resin or resin and spot welds,” he continues.

“Frankly, it looks like a bit of a Frankenstein situation when you look at it all together.” Musk then talks about how sealing the gaps between the different pieces in the body is a nightmare. “That might be the most painful job in the factory, is spackling on the sealant,” he describes, mentioning how even a small error can cause leaks and NVH problems.

Advertisement

Munro asks why newer Model 3s still make use of such a multipiece rear body design instead of a single casting like on the Model Y. “It’s hard to change the wheels on the bus when it’s going 80 mph down the highway,” Musk responds, saying the Model 3 represents such a large portion of the automaker’s volume that the company “[needs] an opportunity to redo the factory without blowing up the cashflow.”

He talks about how important going to a single-piece casting was for the Model Y: There are no gaps, there’s no sealant and there’s no risk of galvanic corrosion at the interface of dissimilar metals. That choice alone, Musks says, allowed Tesla to reduce its body shop size by 30 percent. “We got rid of 300 robots just with that rear body casting,” he tells Munro.

Advertisement

Musk then discusses with Munro the plans for Tesla to move to a structural battery pack that leverages the individual cells as structural elements that resist shear forces. “The cells today in every car are carried like a sack of potatoes,” Musk explains. “They actually have negative structural value,” going on to say how today, cells don’t make vehicles any more rigid, and that especially because there is isolation material needed between the cells themselves and the pack housing to help the batteries handle shock loads, batteries are just a liability from a mass standpoint. Musk wants to change that, and get dual use from those batteries.

The rest of the interview remains thoroughly nerdy. There’s discussion about cars’ natural frequencies, about how reducing polar moment of inertia by bringing mass toward the car’s center of mass yields better handling. There’s discussion about tolerance stack-up and how that leads Tesla to almost always err toward fewer pieces and Lego-like parts precision.

Advertisement

Munro mentions his company’s BMW i3 findings, lauding the German automaker’s excellent build quality for the carbon-fiber body. Musk replies that one of his major concerns about use of carbon fiber is that it has a vastly different coefficient of thermal expansion than aluminum or steel, and this can cause fitment issues when the vehicle is subjected to certain thermal environments.

Musk also talks about how Tesla’s casting sizes on the Model S and X were limited because heat treatment led to shape distortion once the part reached a certain size. To facilitate larger castings, Musk states, company’s material scientists had to make a custom alloy that didn’t require an additional treating step after casting.

Advertisement

Musk also mentions that he wants to do away with 12-volt systems on EVs — a holdover from earlier designs and a way to easily integrate already-existing components from prominent auto suppliers. A 48-volt system, Musk and Munro agree, could have lots of benefits including reduced wire size and weight. Musk mentions that the S and X are now getting lithium-ion 12-volt batteries, which add capacity and last longer than traditional lead-acid ones.

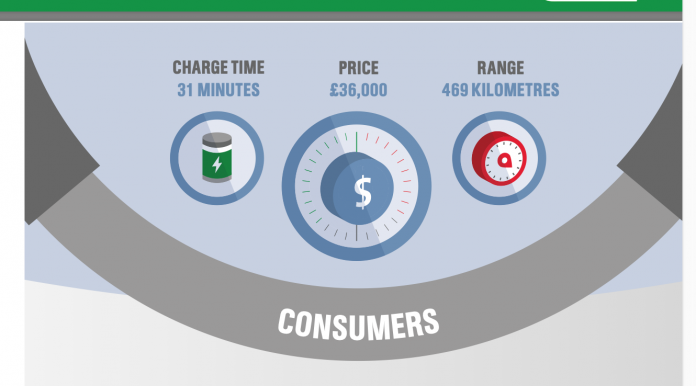

The discussion concludes with talk about the future of EVs and the speed with which they will enter the marketplace in coming years. There’s also talk about shortsellers because of course there is.

Advertisement

Throughout the interview, especially in the beginning, Munro compliments Tesla’s excellent seats, with Musk talking about how the key is to reduce pressure peaks on the body. The two enginerds examine the value of making seats in-house versus buying them from suppliers.

It’s all nerdy and fascinating, and in some ways, a truly magical moment between two total math and science geeks. I love it. I also love how, when Munro says he was having issues with Tesla’s Autopilot driver-assistance system because of bad road markings in Texas, Musk straight-up says: “Even if the road is painted completely wrong and a UFO lands in the middle of the road, the car still cannot crash and still needs to do the right thing…It can’t be dependent upon the road markings being correct….It’s just gotta be ‘no matter what, it’s not gonna crash.’”

Advertisement

The whole interview is just gold. I talked with Munro & Associate’s president Cory Steuben, and he told me about how this interview even came to be. Steuben and Munro are in the middle of a road trip right now in a Model 3 that they spontaneously decided to purchase.

The two planned a trip out west to see some EV automakers, and hung out in Fremont to see if Musk would be there. He wasn’t. Serendipitously, Steuben received an email from an individual saying he could set up an interview with Musk. Musk’s assistant, at 11 p.m. on Monday, scheduled an interview in Boca Chica, Texas for Friday, but by that time, Steuben and Munro were in Eugene, Oregon.

Advertisement

So Steuben and Munro had to bee-line it 2,500 miles, 40 hours in the Model 3, planning charging stations and really putting electromobility to the ultimate test in driving from Oregon all the way to Texas to see the king of EVs himself, Elon Musk.

Luckily, Steuben and Munro made their meeting, with the former saying the billionaire came off as “one of the most enjoyable, humble, stoic…people that I’ve met who’s in a position like that.”

Advertisement

Musk, Steuben said, spent three hours with the two engineers from Michigan, and was seen working at 10:30 p.m. on a Friday.

As if the interview weren’t epic enough on its own.

For GREAT deals on a new or used INFINITI check out INFINITI of Thousand Oaks TODAY!